Tension Monitoring System

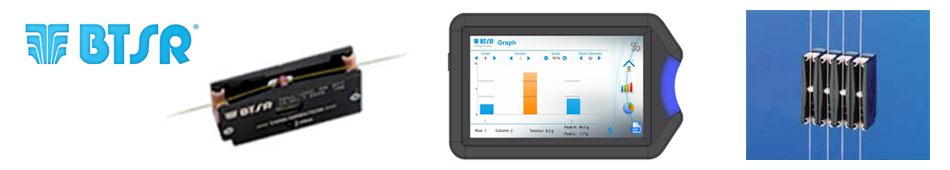

The BTSR tension monitoring system, consisting of a touchscreen control terminal and TS55 series programmable sensors, represents the BTSR solution for tension measurement and monitoring of a yarn put under control in the course of a textile process.

This product has been designed for applications on yarn processes, such as warping, heatset, texturing, extrusion, etc..., which, during the product processing, require an accurate control, aimed at the yarn quality. The accurate control is made possible by the use of TS55 (Tension Smart Scanning Sensor) device, capable of performing an exact measurement and analysis of the yarn tension.

High accuracy and repeatability are assured by the exclusive digital technology (Digital Signal Processor) developed by BTSR, based upon the use of a loading cell which converts the tension exerted by the yarn into a digital signal.

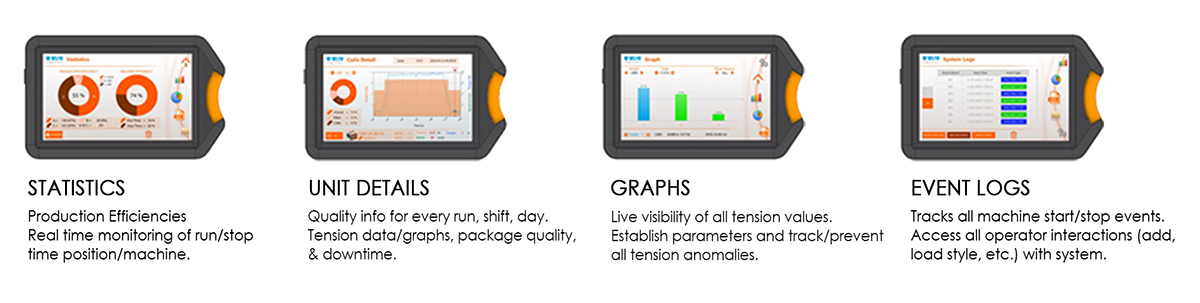

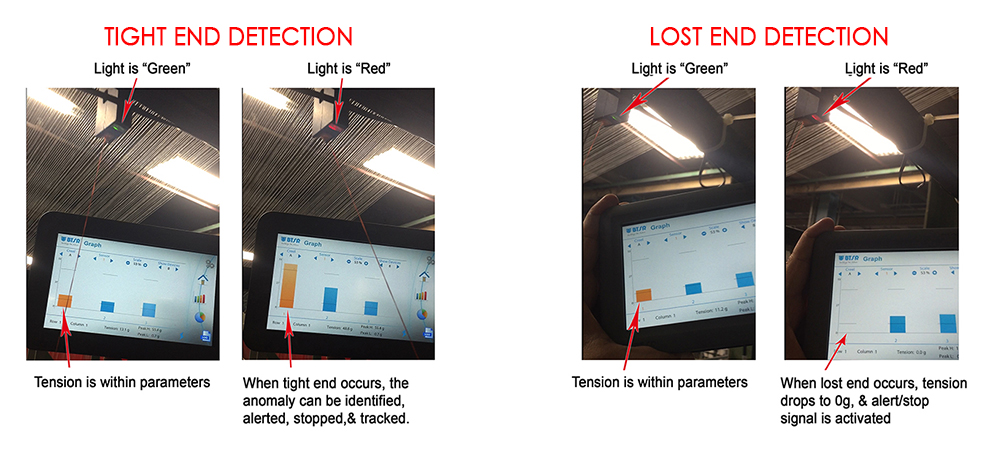

1. TENSION MONITORING - The Touch Matrix control terminal, combined with the TS55 devices installed along the process, provides several and advanced programming functions. You may program the rated tension of the yarn, as well as the maximum and minimum tensions, beyond which the position shall be stopped, thus allowing the control of multiple yarns through a single TS55 sensor, and signaling with utmost certainty and timeliness any lack or excess of filament. You may also detect the peak tension, which allows you to locate the detailed causes of sudden tension variations.

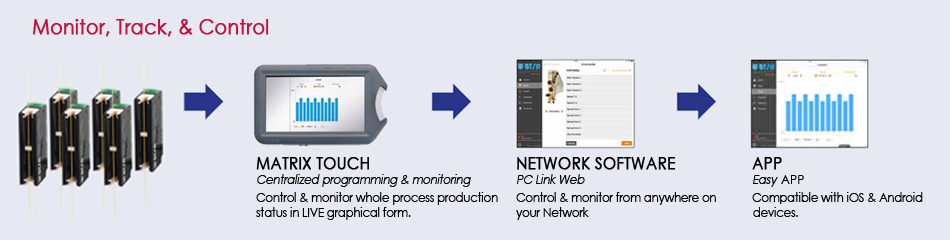

2. PRODUCTION MONITORING - For all our sensors, PC Link Web provides LIVE production tracking which can connect to our Network software, giving you automation at multiple levels. This cloud based system monitors & tracks all yarn stops, breaks, & doffs for showing production/waste in real time. It can also connect to any PC or smartphone to give you instant visibility of your production from anywhere in the world.

Automated Stops & Alerts - BTSR's automated alert system makes the operator immediately aware of any problems & helps the operator quickly identify where the stop is located.

24/7 Operator Management - BTSR let's you manage your employees when your not there. You can effectively monitor & track detailed performance data for every operator shift, & day.

LIVE Production Status - Know your exact production, waste, & efficiencies 24/7. You can immediately react rather than waiting until the next day for production calculations. View from anywhere on your network or smart phone.

Additional Info & Videos

Demo of tight/lost end detection

Quick demonstration of the tension system catching tight & lost ends in warping.

Presentation: Tension Monitoring

From extrusion to warping, tension trial data is shown & explained.